New batteries

for electric vehicle performance

In a changing automotive market, Ampere, the European specialist for intelligent electric vehicles, is playing a pioneering role by reinventing the Renault Group’s strategy for electric batteries. By integrating technologies such as Lithium Iron Phosphate (LFP) and Cell-to-Pack solutions, we are firmly committed to an innovative approach aimed at significantly reducing the costs of electric vehicles, to make them accessible in Europe.

Chemistry of electric batteries: a wide range of technologies for each use

Because chemistry accounts for 30-40% of the price of an electric vehicle battery, Ampere is committed to constantly improving this technology.

The currently used Nickel Manganese Cobalt (NMC) battery technology maximizes the energy density and thus the autonomy of vehicles. Nevertheless, the volatility of markets and prices for rare metals such as nickel and cobalt has a significant impact on the price of these batteries. By integrating the Lithium Iron Phosphate (LFP) technology in addition to the NMC batteries, Ampere has reached a strategic turning point by expanding its offer. Less energy-dense but more affordable, this new technology offers customers optimal autonomy without increasing prices. A key solution for the democratization of electric mobility in Europe.

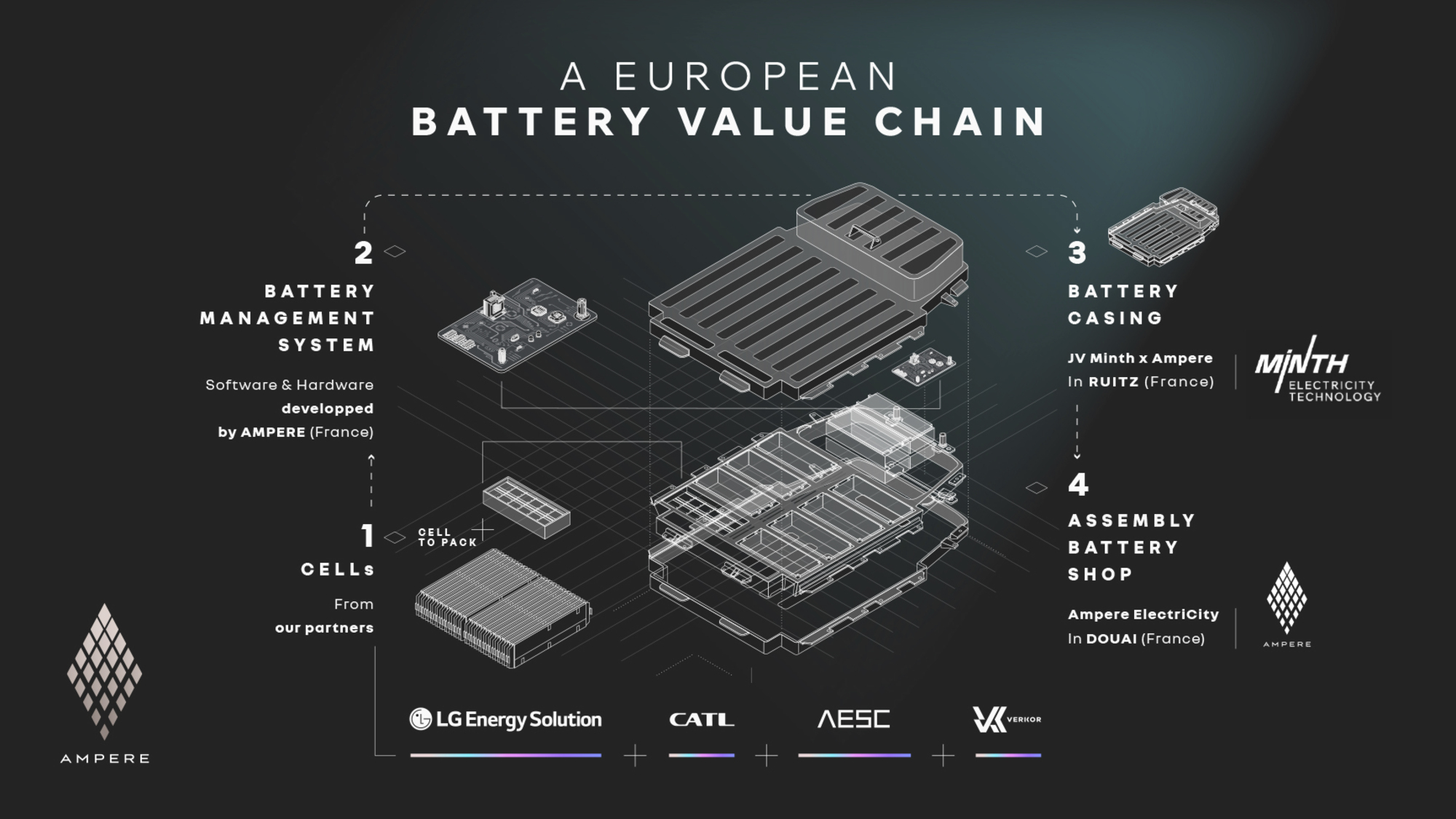

Together with our partners LG Energy Solution and CATL, we are developing a European value chain to ensure optimal efficiency for LFP technology. This strategic approach aims to strengthen the competitiveness of this battery chemistry, intended to equip several models of the Renault and Alpine series, while meeting the needs related to this technology until 2030.

The battery strategy Ampere in the short term: the deployment of LFP chemistry explained by Mohamed Taggougui, Expert Leader Electrochemistry & cells Batteries and Léna Le-Rest, Head of Business Batteries..

These technologies, integrated in 18 months, a record time, make it possible to offer customers the best autonomy at the best price, according to their use. It is essential to Ampere’s mission of democratizing the electric vehicle in Europe.

In the mid-term, Ampere is also working on the development of a battery technology “cobalt free and silicon” allowing recharging in less than 10 minutes, with improved autonomy and reduced costs. Finally, in the long term, the Ampere teams will propose a chemistry based on Lithium metal that doubles the autonomy obtained with the NMC while maintaining the same cost as the LFP chemistry.

The mid-term and long-term Ampere battery strategy: the «cobalt free» and lithium metal chemistry explained by Mohamed Taggougui, Expert Leader Electrochemistry & Batteries cells.

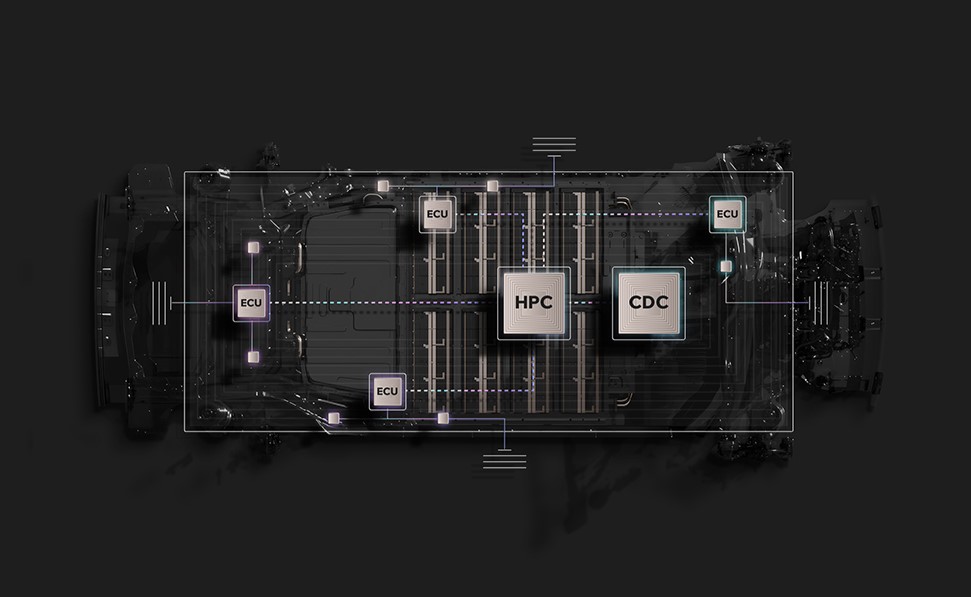

Cell-to-pack innovation: a world Première

In parallel to the LFP technology, Ampere is partnering with LG Energy Solution to develop the innovative «Cell-to-Pack» technology. This revolutionary solution allows the pouch cells to be directly integrated into the vehicle battery housing, eliminating the need for separate modules. By increasing the number of cells in a given space, the “Cell-to-Pack” technology increases vehicle autonomy while reducing production costs.

From 2026, the integration of LFP (Lithium-Iron-Phosphate) and «Cell-to-Pack» technologies will reduce battery costs by about 20%, a decisive step towards making electric vehicles more accessible

Open innovation: an open approach with reference partners

Ampere’s success is based on an open innovation strategy, built around strong partnerships with the best players in the industry. In addition to LG Energy Solution and CATL, we work with AESC and Verkor to ensure maximum technological diversity and flexibility. Ampere now has four leading battery partners in Europe to provide the best solution at the best cost for each of its models. The batteries are assembled by Ampere ElectriCity, at the Manufacture of Douai, in the Hauts-de-France.

In a fast-changing and competitive environment, our battery strategy is proof of the efficiency of Ampere’s open and horizontal approach with best-in-class partners, ensuring smart capital allocation, flexibility and rapid execution. This plan is in line with Ampere roadmap to reduce costs by 40% before the next generation of vehicles.

A laboratory for more innovation

Ampere’s battery strategy will be powered by a Innovation Battery Cell Laboratory that will open these doors after the summer of 2025. With this Laboratory, Ampere is equipping itself with a cutting-edge tool to provide guidance to the company regarding technological strategy, bring technological breakthroughs in the electric vehicle market and create value through innovation activities.

Our battery chemistry and Cell-to-Pack solutions strategy is a testimony to our ambition to lead the transition to electric mobility in Europe. By combining innovation, competitiveness and partnership,

Ampere aims to rapidly transform the automotive industry and make electric vehicles accessible to as many people as possible.

CONTINUE

EXPLORING